Many industrial marking applications use inkjet markers or laser marking systems. Let's try to understand how both systems work in order to select the best option for your application. Then we'll list their benefits and drawbacks, and you'll be better equipped to choose the best solution for your application.

Although both laser marking machines and inkjet printers are used to do marking on products,

people are often perplexed as to which to use.

Ink Jet Printer

In fact, the purpose of laser marking and inkjet coding is the same,

both for the marking products, but their respective operating principles are very different.

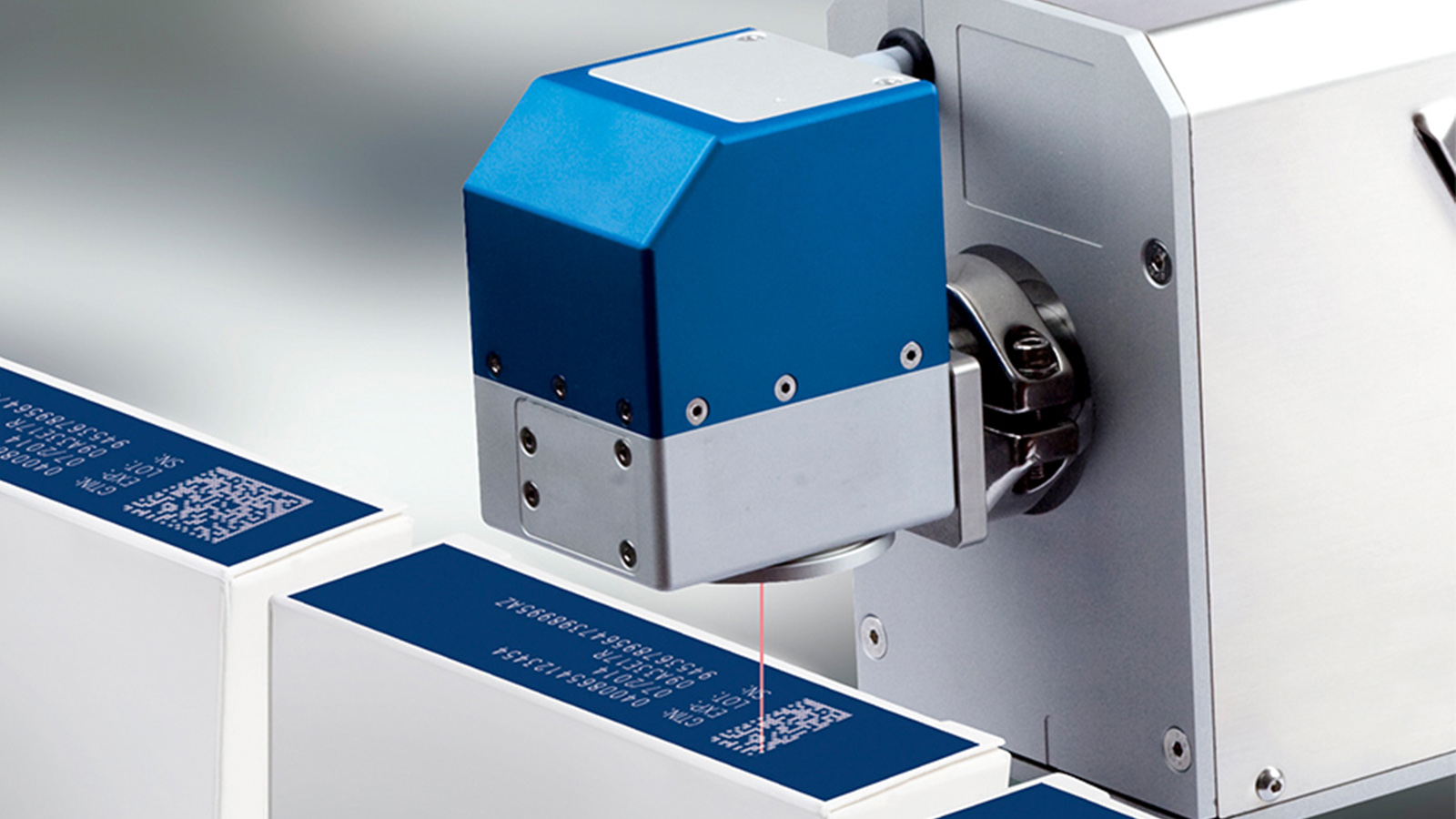

Laser marking machines use laser beams to reveal the deep of material or cause physical changes in the object,

then operational traces appear so that the material emerges with the desired graphics, images, text, and other permanent marks.

Laser marking processing is divided into two types: thermal processing and cold processing.

Thermal Laser

Cold Laser

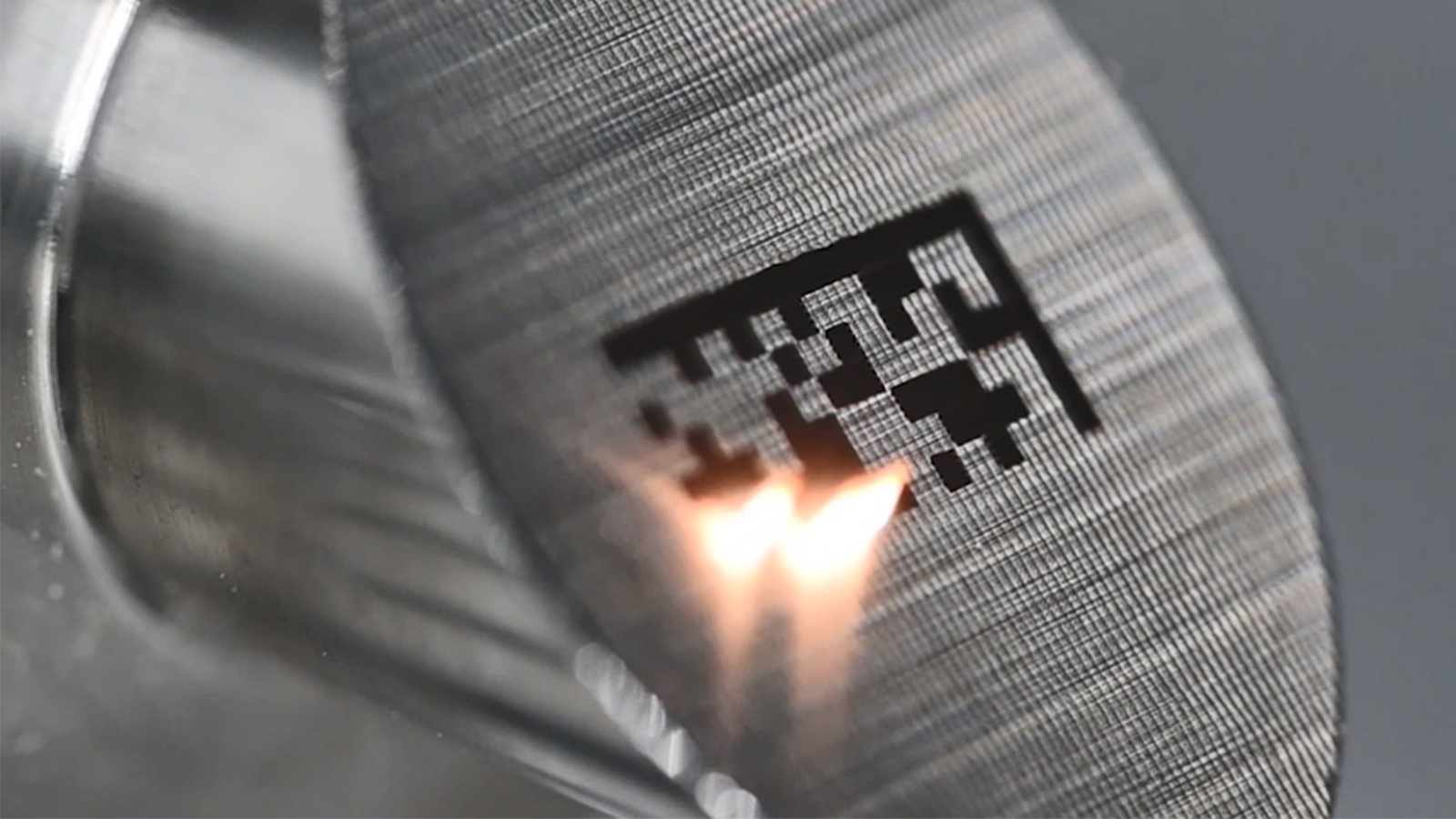

In thermal processing, a high-energy-density laser beam is irradiated on the surface of the material being processed.

The absorbed laser energy causes a thermal excitation process in the irradiated area,

causing the temperature of the material surface (or coating) to rise,

resulting in metamorphism, melting, ablation, evaporation, and other phenomena.

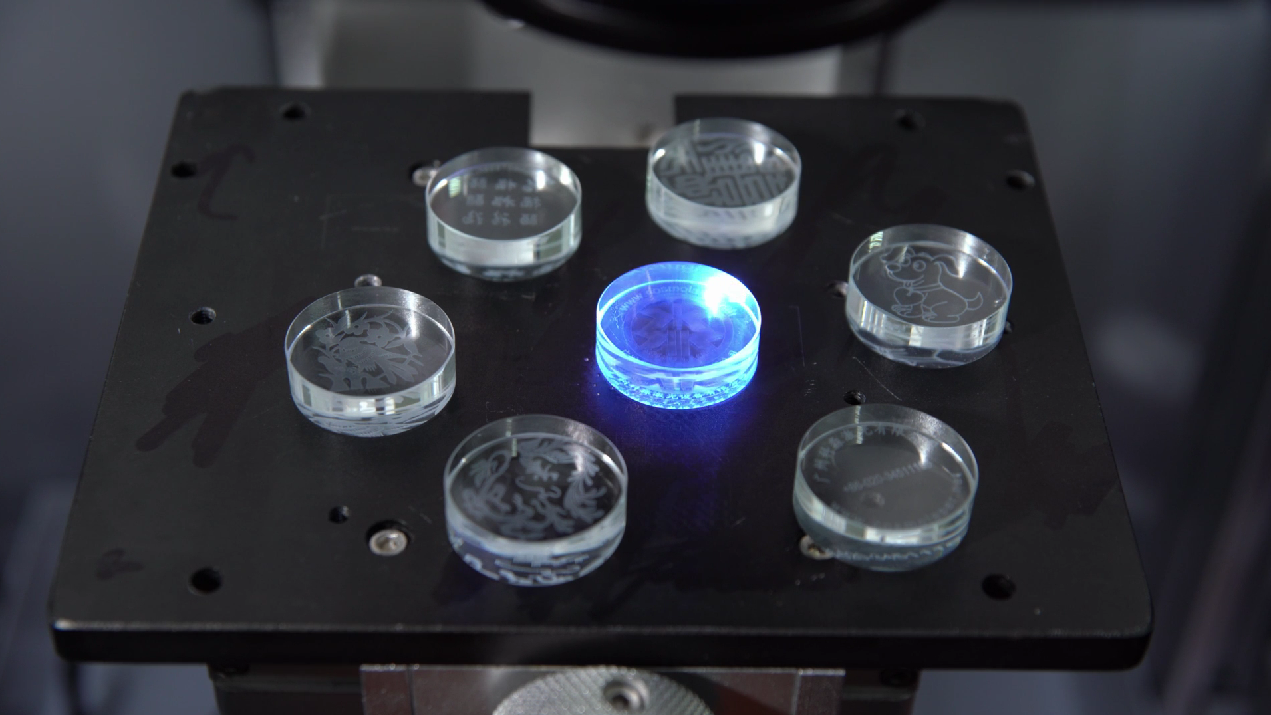

Cold processing refers to photons with very high loading energy (ultraviolet/green light, etc.),

which can modify materials (especially organic materials) or nearby media to cause non-thermal process damage to the material.

This type of cold processing is essential in the laser mark marking process.

Because it is not thermal ablation, there is no thermal damage,

and thus no heating or thermal deformation of the surface being processed and the surrounding area.

And an inkjet printer is one that uses the deflection of the ink charged deflection electric field to deflect the ink out of the normal line of injection shot to the workpiece's surface.

The power applied to the ink droplet charging electrodes can be used to control the position of each ink droplet.

For example, when printing a QR code, only the ink droplet vertical marker line changes,

allowing the object to be printed and the nozzle relative movement to combine each black and white pixel block of the image screen,

resulting in the printing mark on the product coverage.

As a result of the low cost of inkjet printing mark raw materials, printing mark operation is simple to standardize and unify.

While laser marking is more expensive, it can mark in a variety of ways and has a wider range of applications.

In conclusion, we can select a method that is appropriate for their specific product printing labelling situation.

CONTACT US

GET IN TOUCH WITH US

Just leave your email or phone number on the contact form so we can provide you with more services!