When you create different kinds of laser-cut designs by using laser cutting machines, a lot of dust and fumes will be produced. These dust and fumes may bring health and safety risks for workers and the workshop environment, as well as affect the quality and performance of the laser cutting process and result. That's why it is essential to have a dust collector system when laser cutting.

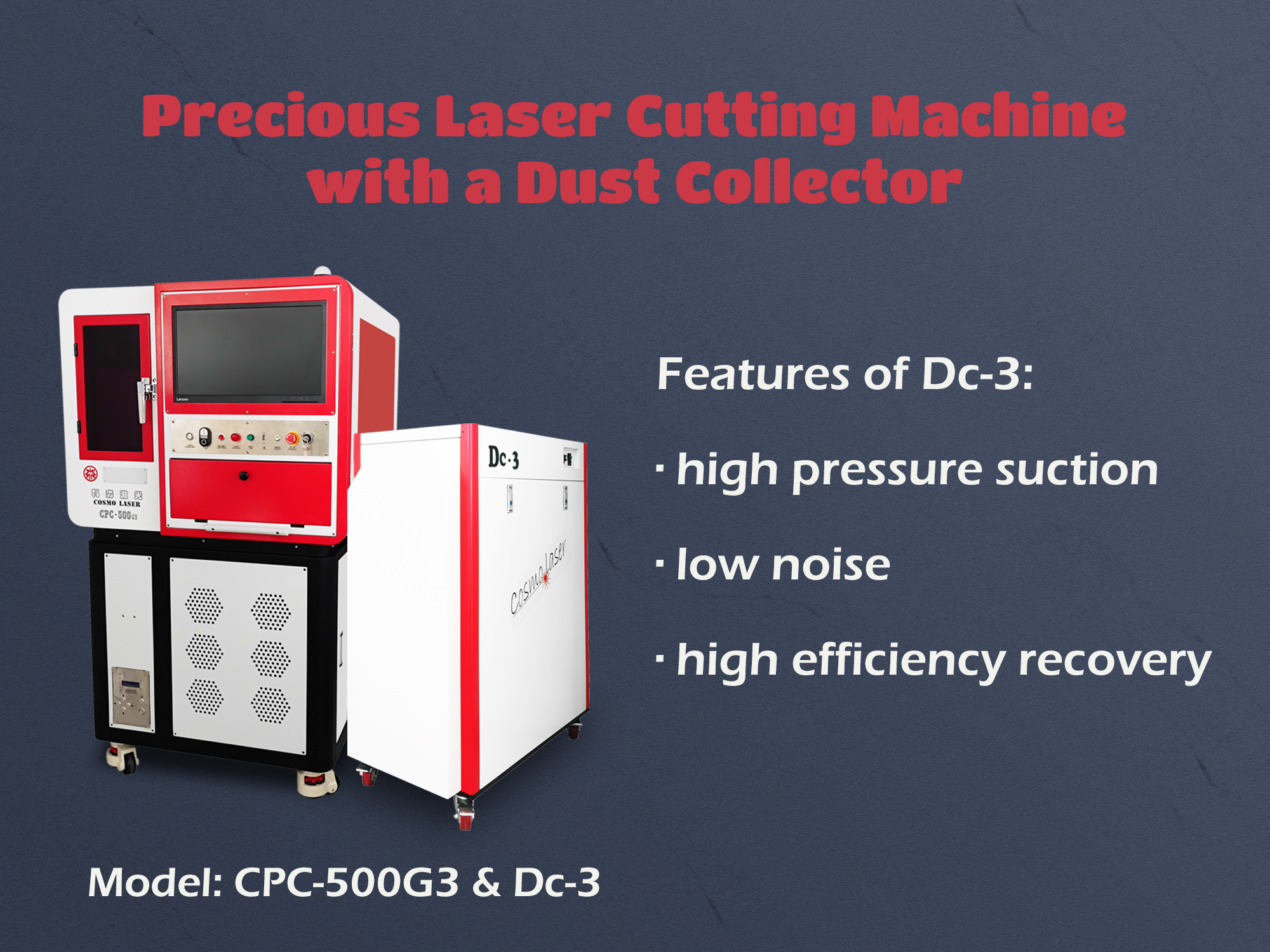

As a one-stop solution provider, Cosmo not only provides good quality laser cutting machines but also good dust collectors. Let's watch this video and see how they work together.

Fully Sealed Design

Link Together

Put it on the side, it doesn't take up much space

Laser processing has 3 characteristics:

1. is using the high energy density of light after passing through a focal lens

2. is by photothermal effect

3. belongs to non-contact processing

During the process, many fine-grained mixtures of dust and fumes will be generated.

So during the cutting and marking of precious metals, the dust and gas need to be processed and recycled in time. If it is not processed in time, it will not only cause high gold loss but also have a certain impact on the health of the operator. It will also affect the quality of the workpiece and the workshop environment. It will also damage the costly laser heads.

Whether it is in terms of environmental impact, machine lifespan, employee health, and production costs and benefits of the enterprise, laser processing needs to be equipped with a tailored DC-3 environmentally friendly vacuum dust collector.

CONTACT US

GET IN TOUCH WITH US

Just leave your email or phone number on the contact form so we can provide you with more services!