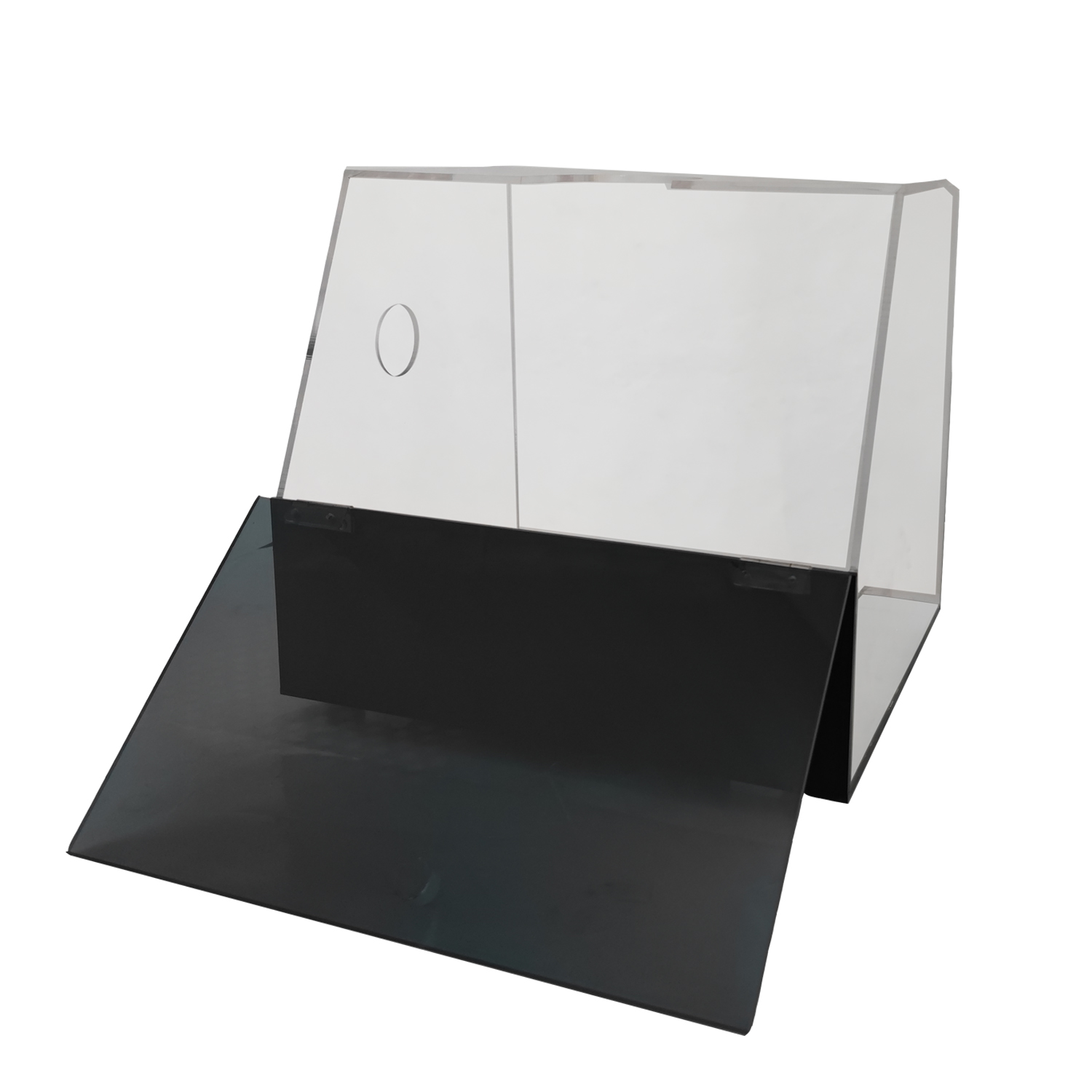

The Dc-2 adopts an integrated cabinet structure, high-pressure suction, and high-efficiency recovery with an exquisite design. Equipped with a high-efficiency motor, it can operate at a high-performance rate and for long hours. The dust collector suction strength is adjustable accordingly to different demands. It is equipped with a differential pressure sensor to monitor the operating status of the equipment at any time. Filter maintenance and replacement are simple and can be easily accessed by opening the machine's top cover. Suitable for a wide range of industries, applications and materials which generate a large amount of dust. The device can absorb and effectively improve the working environment. Laser engraving, cutting and welding of metal, paper, plastic, PCV, rubber, glass, etc are some applications suitable for dust collector use.

Laser processing has 3 characteristics:

1. is using the high energy density of light after passing through a focal lens

2. is by photothermal effect

3. belongs to non-contact processing

During the process, many fine-grained mixtures of dust and gas will be generated.

So during the cutting and marking of precious metals, the dust and gas need to be processed and recycled in time. If it is not processed in time, it will not only cause high gold loss but also have a certain impact on the health of the operator. It will also affect the quality of the workpiece and the workshop environment. It will also damage the costly laser heads.

Whether it is in terms of environmental impact, machine's lifespan, employee's health, and production costs and benefits of the enterprise, laser processing needs to be equipped with a tailored DC-2 environmental friendly vacuum dust collector.

CONTACT US

GET IN TOUCH WITH US

Just leave your email or phone number on the contact form so we can provide you with more services!