The vacuum precious metal collector machine(model: Dc-3) adopts an integrated cabinet structure, high-pressure suction, low noise, and high-efficiency recovery with an exquisite design. It is specially designed for precious metals cutting machines and CNC design cutting machines with perfect integration with the equipment. Equipped with a turbo vacuum pump, a built-in suction power adjustment system, and a filter barrel to ensure high-level filtration accuracy and efficiency.

acrylic cover in the cutting machine

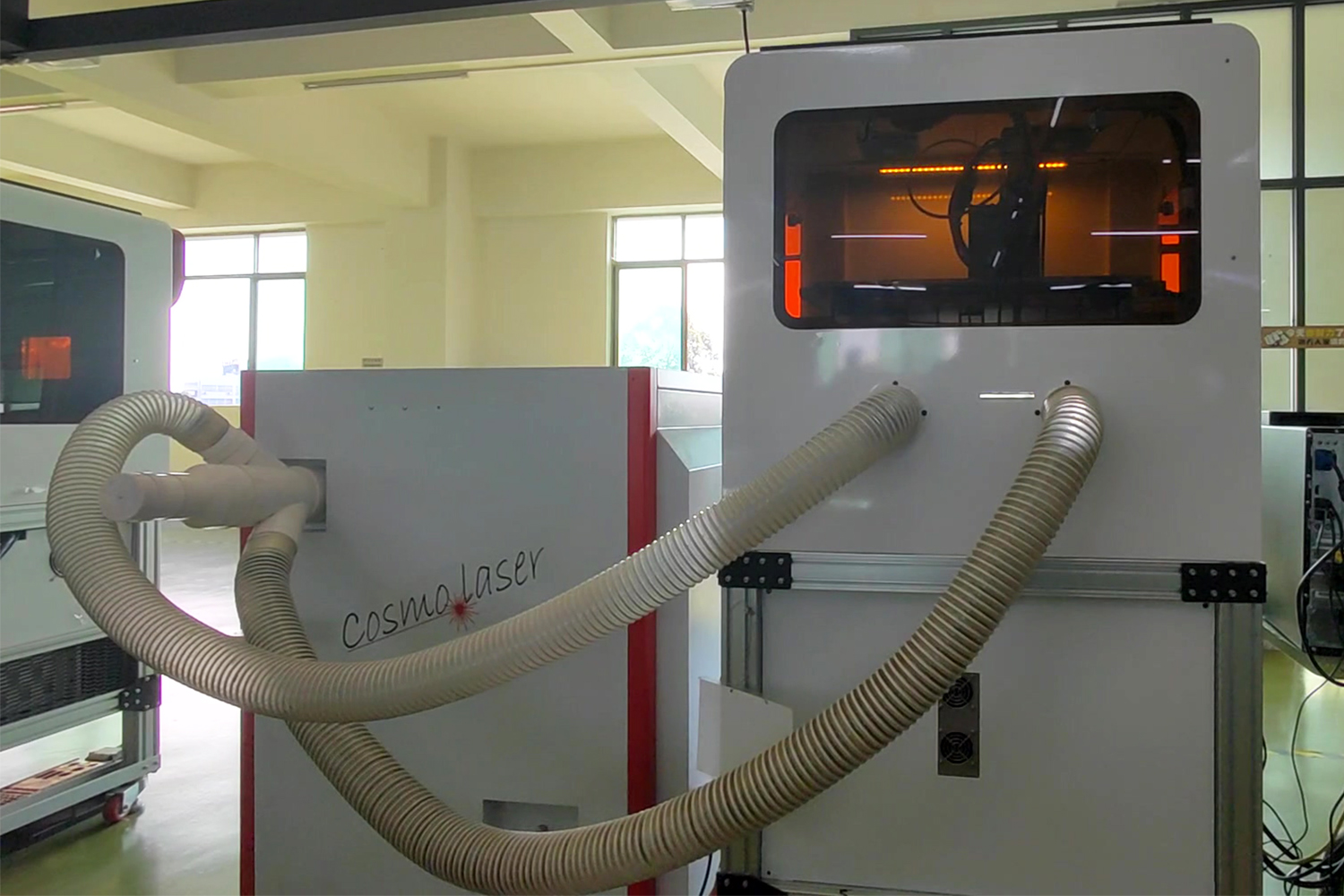

dust collector with pipes

works together

Laser processing has 3 characteristics:

1. is using the high energy density of light after passing through a focal lens

2. is by photothermal effect

3. belongs to non-contact processing

During the process, many fine-grained mixtures of dust and gas will be generated.

So during the cutting and marking of precious metals, the dust and gas need to be processed and recycled in time. If it is not processed in time, it will not only cause high gold loss but also have a certain impact on the health of the operator. It will also affect the quality of the workpiece and the workshop environment. It will also damage the costly laser heads.

Whether it is in terms of environmental impact, machine's lifespan, employee's health, and production costs and benefits of the enterprise, laser processing needs to be equipped with a tailored DC-3 environmental friendly vacuum dust collector.

CONTACT US

GET IN TOUCH WITH US

Just leave your email or phone number on the contact form so we can provide you with more services!