The Cosmo Double View Laser Welding Machine's combination of microscope and CCTV display monitor provides flexibility, accuracy, and operator comfort. Whether you're crafting intricate jewellery designs or working on industrial projects, this dual-view system ensures exceptional results!

This blog will introduce the microscope and CCTV viewing methods and how to choose one when using our machine. At last, we share some jewellery applications of the Cosmo laser welding machine.

The microscope view is the traditional method used in laser welding machines. It involves using a high-quality microscope to observe the welding process.

Here's how it works:

- The operator peers through the microscope eyepiece to focus on the welding area.

- This method provides excellent magnification and clarity, allowing precise alignment of the laser beam.

- However, it can be physically demanding for the operator, especially during prolonged welding sessions.

Besides viewing through the microscope, the operator can also observe the welding process on a larger screen.

Benefits of the CCTV display monitor view:

- Comfort: Operators can maintain a more comfortable posture while monitoring the welding process.

- User friendly for people with myopia or others who must wear glasses

- For novices, the CCTV type is easier to use than the microscope type

When deciding which viewing method to use, consider the following factors:

1. Precision vs. Comfort

- Microscope View: Ideal for intricate work that demands utmost precision.

- Monitor View: Offers comfort during long welding sessions without compromising accuracy.

2. Operator Preference

- Some operators may prefer the traditional microscope view due to familiarity.

- Others may appreciate the convenience of the monitor view.

3. Application

- For delicate jewellery pieces or fine components, the microscope view shines.

- Larger-scale production or repetitive tasks may benefit from the monitor view.

As a result, our double-view laser welding machine can meet all your needs at one time, operators can choose one method according to their operation habits and metal part's characteristics. Last but not least, even though an experienced microscope-type operator leaves the company, new staff can become familiar with the machine soon with the CCTV monitor.

Stereo-Microscope

CCTV Display screen/monitor

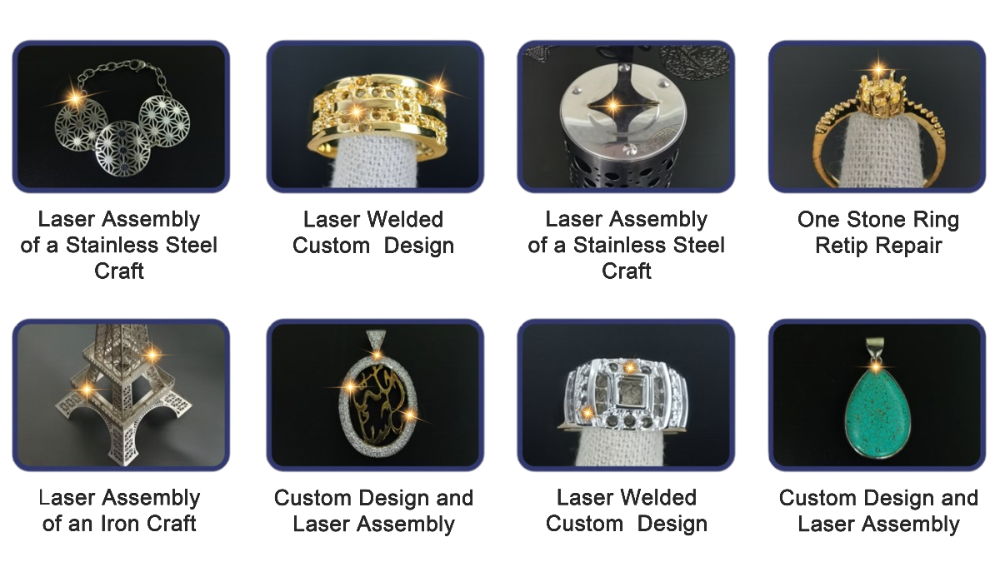

1. Filling Porosity

- Porosity refers to tiny holes or gaps in metal surfaces. These imperfections can compromise the integrity of jewellery.

- Laser welding allows jewellers to fill porosity by precisely melting and bonding the metal, resulting in a seamless surface.

- Whether it's a delicate gold necklace or a platinum ring, laser welding ensures flawless repairs.

2. Prong Retipping

- Prongs hold gemstones securely in place. Over time, they may wear down or become damaged.

- With laser welding, jewellers can re-tip platinum or gold prong settings without removing the stones.

- The focused laser beam allows for pinpoint accuracy, minimizing the risk of heat damage to nearby areas.

3. Bezel Setting Repair

- Bezel settings encircle gemstones with a metal rim, providing protection and enhancing their appearance.

- Damaged bezels can be repaired using laser welding. The process ensures a strong bond without affecting the stone.

- Whether it's a diamond solitaire or a colourful sapphire, laser welding restores the setting's integrity.

4. Manufacturing Corrections

- During jewellery production, defects may occur—such as misaligned joints or incomplete seams.

- Laser welding allows artisans to correct manufacturing defects seamlessly.

- Whether it's a fine filigree pendant or an intricate bangle, laser welding ensures precision.

CONTACT US

GET IN TOUCH WITH US

Just leave your email or phone number on the contact form so we can provide you with more services!