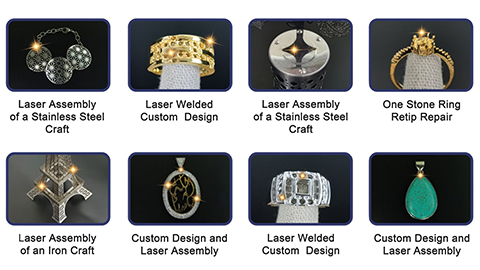

Welding/ repairing is a very important step in jewellery making. The beam of light emitted from a laser welder is concentrated, adjusted and controlled by the operator, in much the same way as the flame of a soldering torch is regulated by a jeweller. However, compared to soldering, laser welding is faster, cleaner and more cost-effective for many manufacturing and repair applications. The benefit of this technology is that very little heat is generated at the weld point, allowing users to easily weld away from the most complicated component parts without damaging heat-sensitive materials.

LASER is an acronym for “Light Amplification by the Stimulated Emission of Radiation” which produces a sharp, focused light beam that melts a very small area of metal. Laser welding uses an amplified beam of light to produce a solid weld with an almost invisible seam in seconds. It sounds complicated but is really quite simple. Laser welding uses a specific wavelength of light to accomplish the welding process.

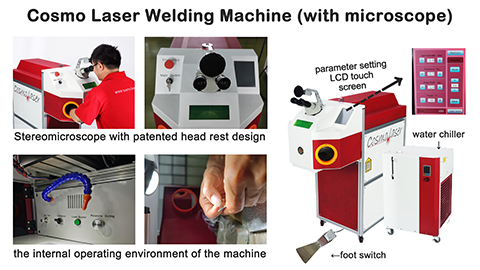

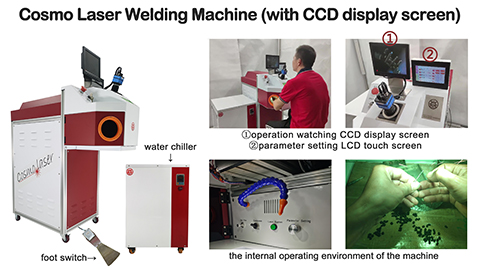

Our machine has two types of visual systems, one is the CCD display screen, and the other is the microscope. You can feel free to choose the one more convenient and comfortable for you.

The microscope type with headrest design helps reduce the operator's fatigue during long-hour operation. Operators hold parts in their hands while clearly viewing the operation in the welding chamber through a microscope. An internal cross-hair allows the operator to easily align and weld the parts at the correct location.

CONTACT US

GET IN TOUCH WITH US

Just leave your email or phone number on the contact form so we can provide you with more services!