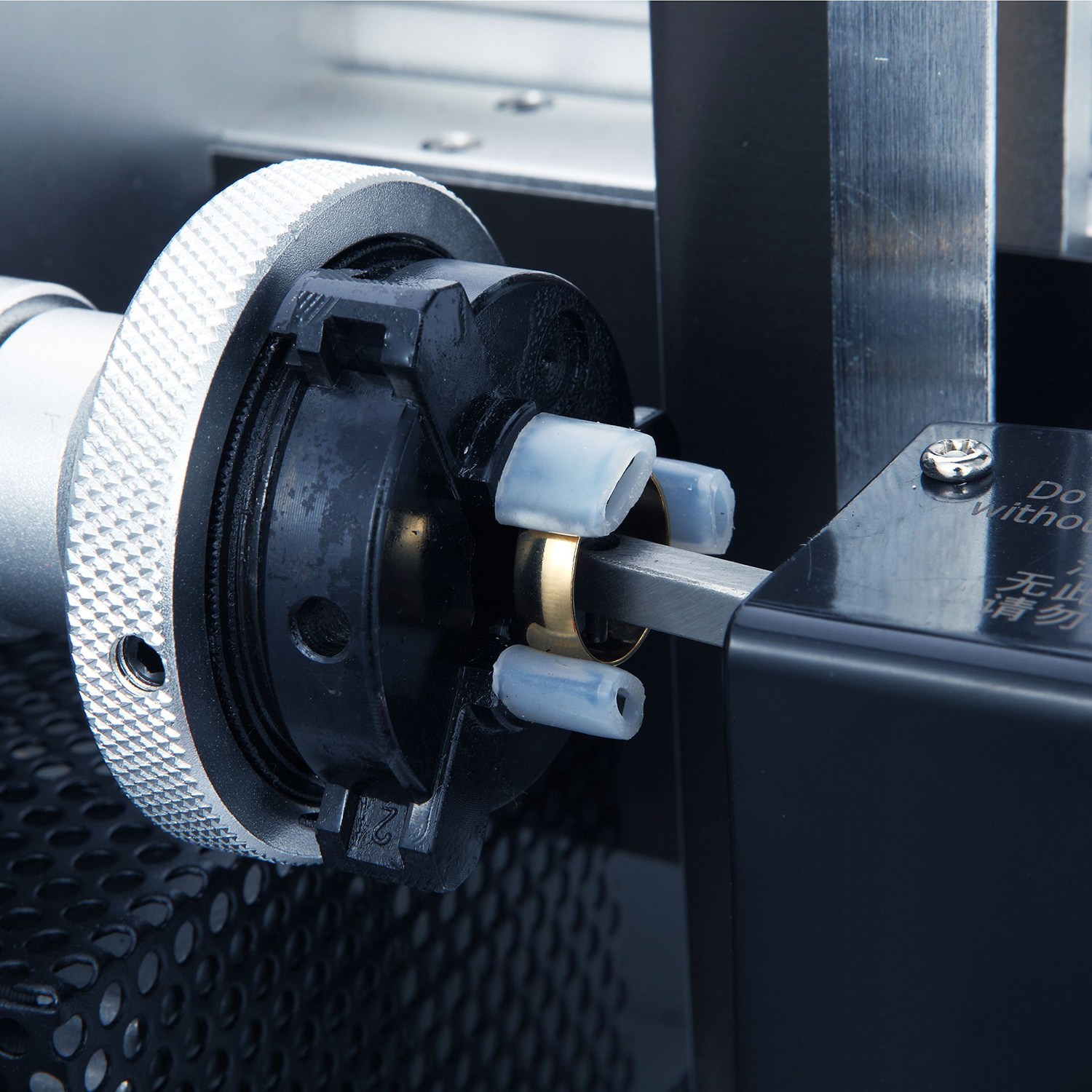

Cosmo dot peen marking machine(CPM-R) is specially created to mark the inside and outside of rings and bangles and also on flat surfaces.

Let's see how its appearance is like?

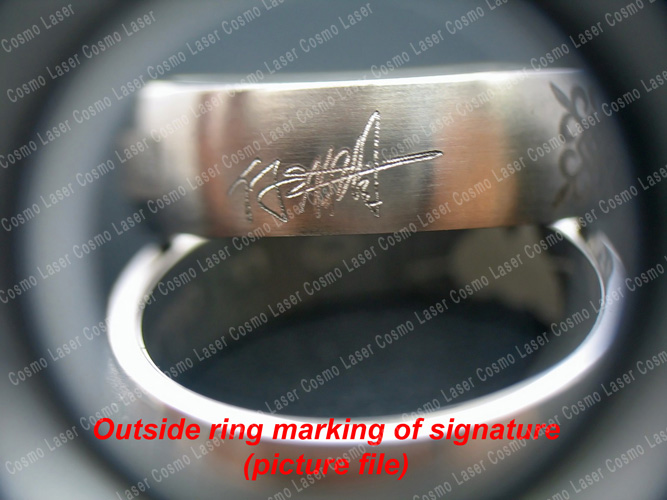

Dot pin marking machine involves using an electrically driven stylus to rapidly strike the surface of the material, creating a series of dots. It uses an industrial-grade diamond pin. It results in shiny marking without any material loss and no need for additional polishing.

/ PRODUCT PROFILE /

Dot peen Marking Machine, also known as a dot pin engraving machine or a dot pin marker, is a type of marking machine that uses a dot pin technology to create permanent marks on various materials.

Dot pin marking machine involves using an electrically driven stylus to rapidly strike the surface of the material, creating a series of dots. These dots form the desired marks, which can include text, numbers, logos, and other symbols. The depth and spacing of the dots can be adjusted to achieve different marking effects.

/ COMPANY PROFILE /

Cosmo Laser Equipment Company Limited is a laser equipment manufacturer integrating R&D, production, sales and after-sales service. Since 2004, Cosmo Laser starts producing high-quality laser equipment for the global jewellery industry, precious metal and gift production fields, such as watches, eyeglasses, hardware products, and electrical appliances. We have a worldwide sales and service network.

Our company pays attention to the transformation of high-tech innovations and the development of the laser industry, adopts new design concepts, and uses software to optimize the combination, which greatly extends the service life of equipment's components and the precision of the equipment.

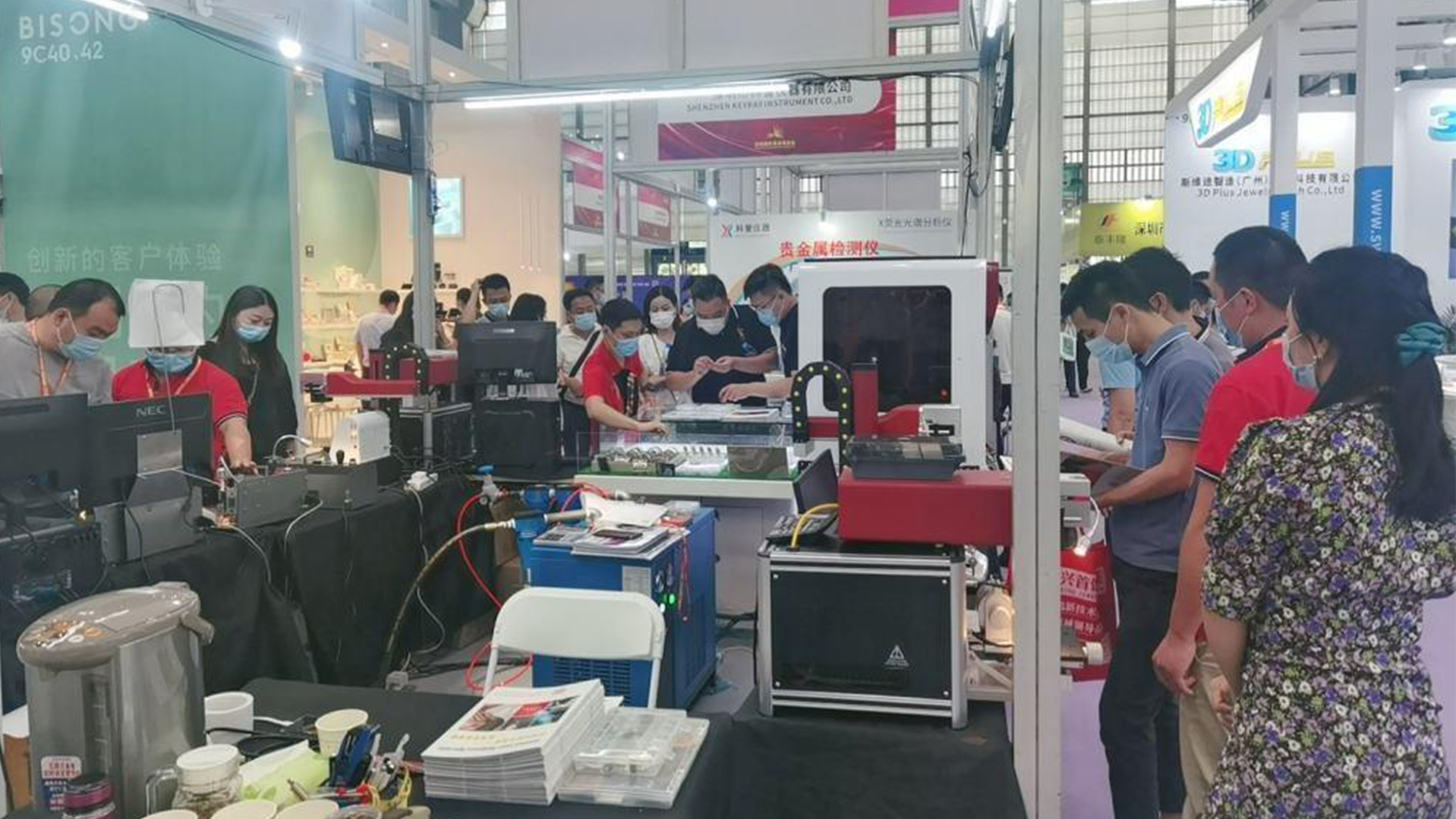

2020 Shenzhen International Jewelry Fair

2019 Hong Kong Jewellery & Watch Fair

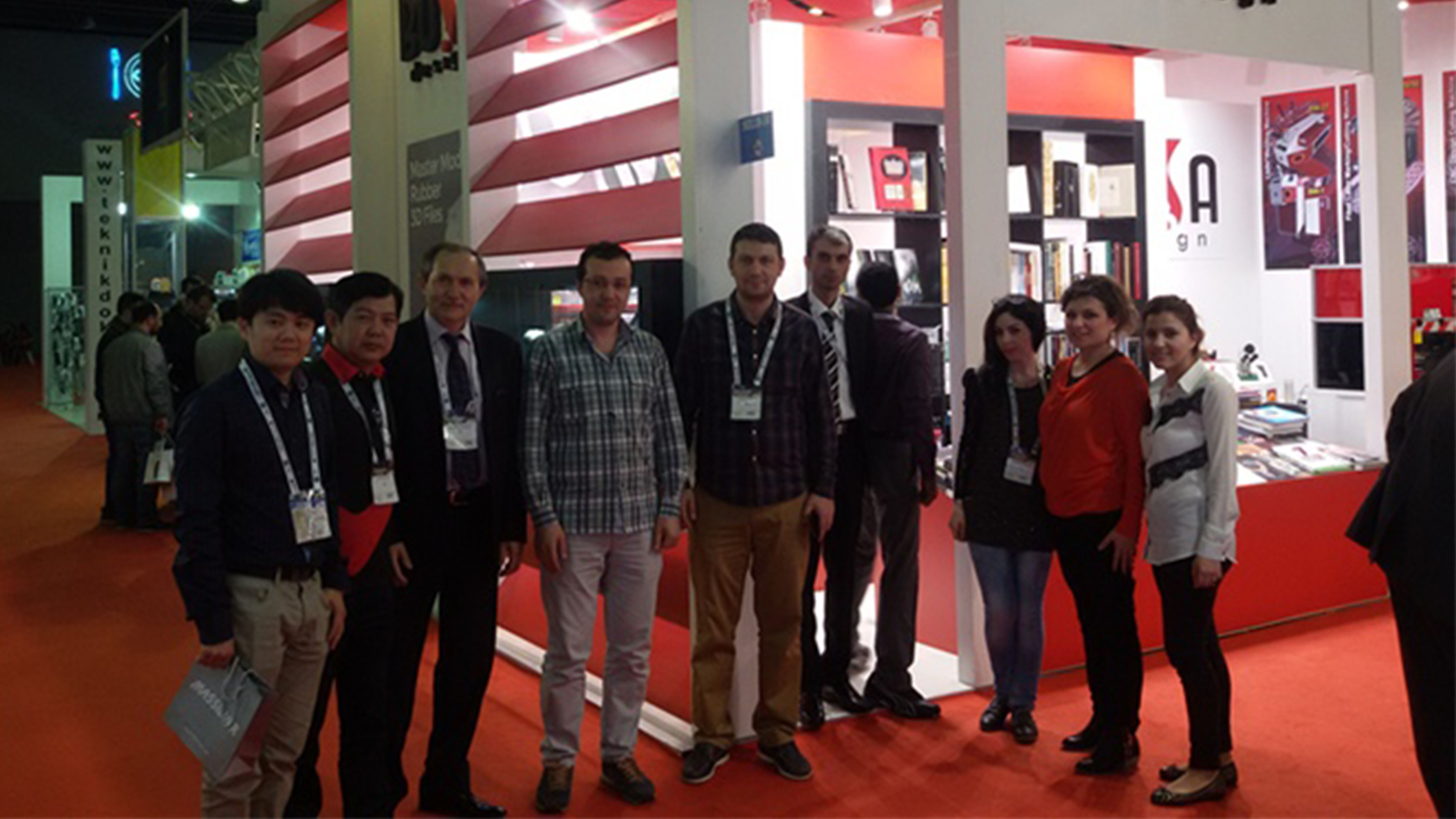

2014 Turkey Jewellery & Gem Fair

01. It is specially designed for the marking of the inner/outer surface of the finger ring/bracelet and flat surface marking.

02. The marking software is in-house-developed and provides an easy to learn and use interface.

03. Compact design takes up minimum working space.

04. Ultra-low power consumption of 75W.

05. Able to mark all WINDOWS compatible fonts, languages, and monochrome bitmap pictures.

06. Able to mark a minimum height of 0.5mm for English characters, 1mm for Chinese characters.

07. Nine azimuth positioning, to ensure the accuracy of marking position, and adjustable marking depth.

08. Marking can be repeated with no ghosting effect.

09. Uses diamond pin for marking to achieve a high brilliance shiny finishing with no additional polishing.

10. Highly recommended for retail shops for added value service to the customers.

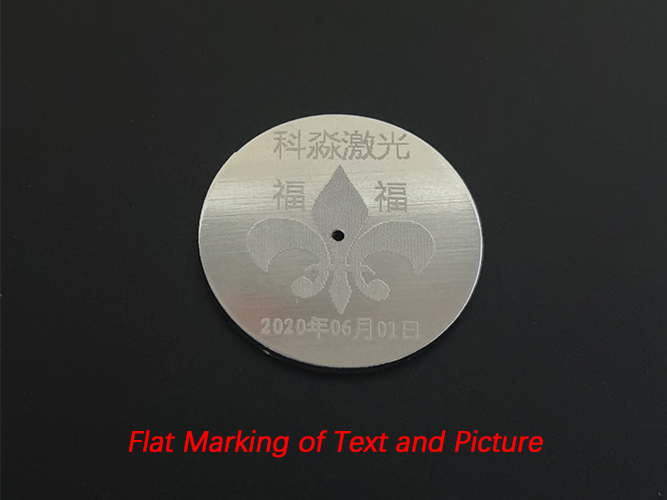

11. Able to mark on a flat surface with an attachment.

Flat Surface Marking

Outside of Bangle Marking

Inside of Ring Marking

CONTACT US

GET IN TOUCH WITH US

Just leave your email or phone number on the contact form so we can provide you with more services!