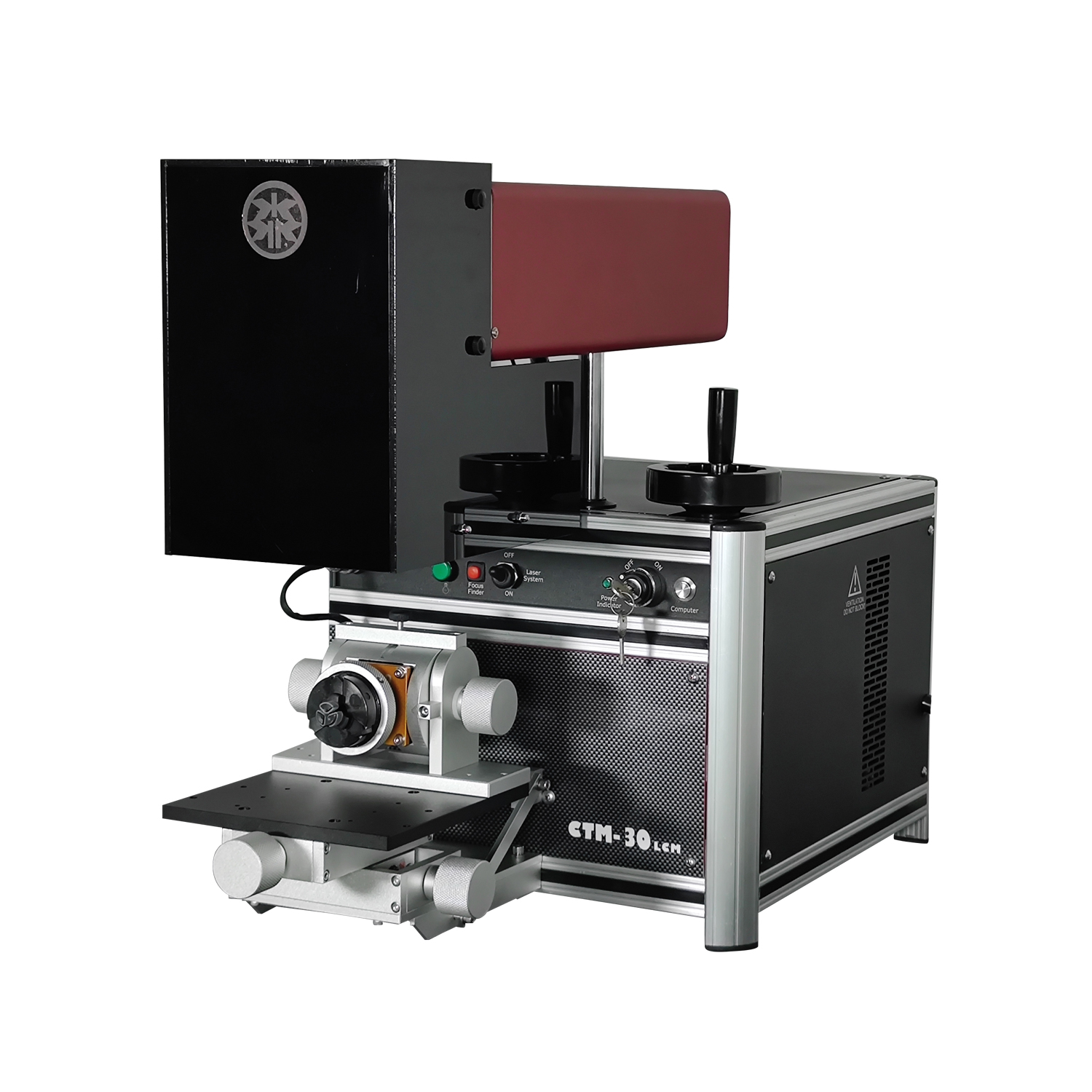

Model CAM-MARK is a fibre laser marking machine with a CCD visual positioning system. Operation Tutorial Videos Including:

- Video1: How To Mark On Outside Ring

- Video2: How to Mark on Inside Ring

- Video3: How to Change the Marking Times and Power

- Video4: How to Reinstall the Software VisionLaser

The page you are visiting is >>>Video1: How To Mark On Outside Ring<<<

With the continuous development of visual detection and technological innovation, the combination with laser marking machines demonstrates technological achievements. The vision-based laser positioning marking machine is an integrated device that combines laser technology and visual technology, with an immeasurable future. Let's analyze its functions and advantages:

1. The vision-based laser positioning marking machine uses lasers controlled by a system to quickly scan and leave imprints on the surface of products, forming information. By incorporating visual technology, it's like giving this laser machine a pair of eyes. With these eyes, the laser machine eliminates the need for manual placement, accurately identifies the products to be marked, and thus improves efficiency while saving labor. The vision-based laser positioning marking machine is a product of the era's development and a transformation of technological civilization.

2. This laser machine applies visual positioning principles. First, it creates templates for products, defining their shapes and saving them as standard templates. During normal processing, the required products are photographed, and the computer performs rapid template comparison and position localization. After adjustments, the products can be processed. This functionality automatically recognizes product features for laser marking, achieving precise positioning. Even small objects can be accurately marked without the need for fixtures, reducing manual involvement and optimizing work efficiency.

3. The main features of this laser machine are automatic recognition and automatic marking. It rarely experiences errors, omissions, or interruptions in marking. It can mark multiple products at once, enabling automated production lines. The vision-based laser positioning marking machine is primarily used for large quantities of small, regular-shaped products. With this, laser marking machines enter a new development stage: the era of visual automation in laser marking.

CONTACT US

GET IN TOUCH WITH US

Just leave your email or phone number on the contact form so we can provide you with more services!