The phone accessory industry is constantly evolving and innovating to meet the needs of consumers. For the manufacturers, to enhance their brand image or meet the needs of customization, identification and traceability, they usually mark some information on their products. In the past, most manufacturers used the methods of inkjet coding or label pasting.

One of the latest trends is the use of UV laser markers to mark logos, serial numbers, QR codes and other information on the chargers. UV laser markers have many advantages over traditional methods, such as high precision, fast speed, low cost, environmental protection and anti-counterfeiting. UV laser markers can mark without damaging the surface or affecting the performance of the phone chargers. Therefore, UV laser machines become more and more popular.

- Introduction -

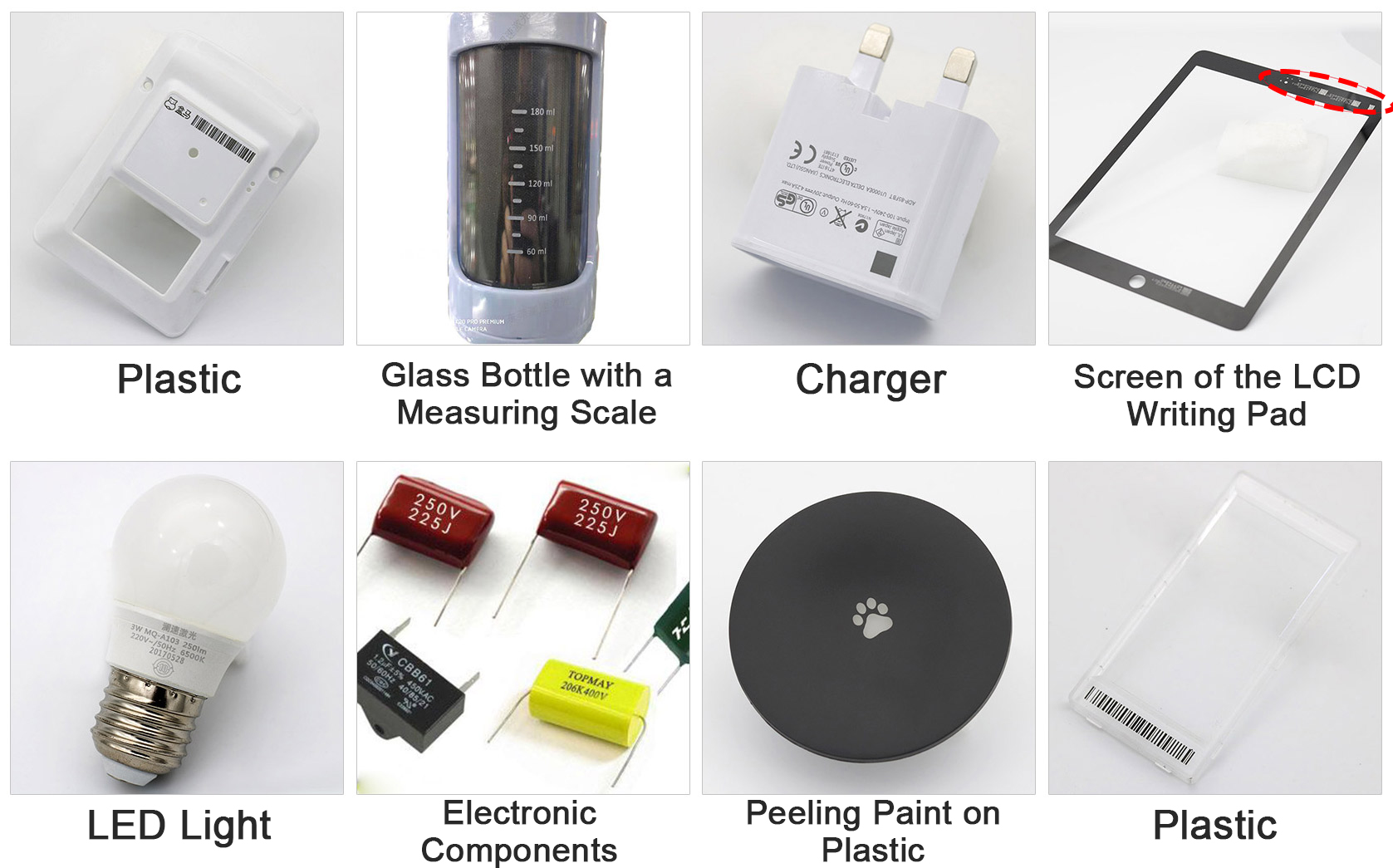

UV laser markers are widely used in the phone charger industry for various purposes, such as marking logos, serial numbers, barcodes, QR codes, and other information on the surface of the chargers. UV laser markers have many advantages over traditional marking methods, such as high precision, high speed, low cost, and environmental friendliness. The UV laser marking machine can mark on all plastic chargers such as ABS, PC, PVC, PE, and PP. The marks are smooth and neat, without burrs or deformation.

UV lasers use a highly absorbable wavelength (355 nm) to mark parts. This high absorption rate allows UV lasers to perform "cold marking". As a result, UV lasers are ideal for applications that require high-contrast or minimal product damage. Besides the phone charger industry, UV laser markers also have many other applications in different fields, such as:

- Medical devices: UV laser markers can mark medical instruments, implants, syringes, tubes, bottles, and other devices with high hygiene and safety standards. The marks are easy to read and trace and can prevent counterfeiting and tampering.

- Cosmetics: UV laser markers can mark on cosmetic products, such as lipstick, mascara, nail polish, perfume, and lotion. The marks are elegant and attractive and can enhance the brand image and customer loyalty.

- Electronic components: UV laser markers can mark electronic components, such as PCBs, ICs, LEDs, resistors, capacitors, and connectors. The marks are precise and reliable and can improve production efficiency and quality control.

- Various transparent items: such as glass, crystal, acrylic, and plastic. The UV laser beam has a high energy density and a small spot size, which can create precise and clear marks on the surface or inside of the transparent material.

- Jewellery: UV laser marking machines are used in the jewellery industry to make personalized and creative permanent markings on jewellery such as gold and sterling silver. Compare to the fibre laser, the UV laser can minimise heat stress when marking. Because of this, no residue of burrs or yellow tinting is left over on the metal.

- Cosmo's Choices -

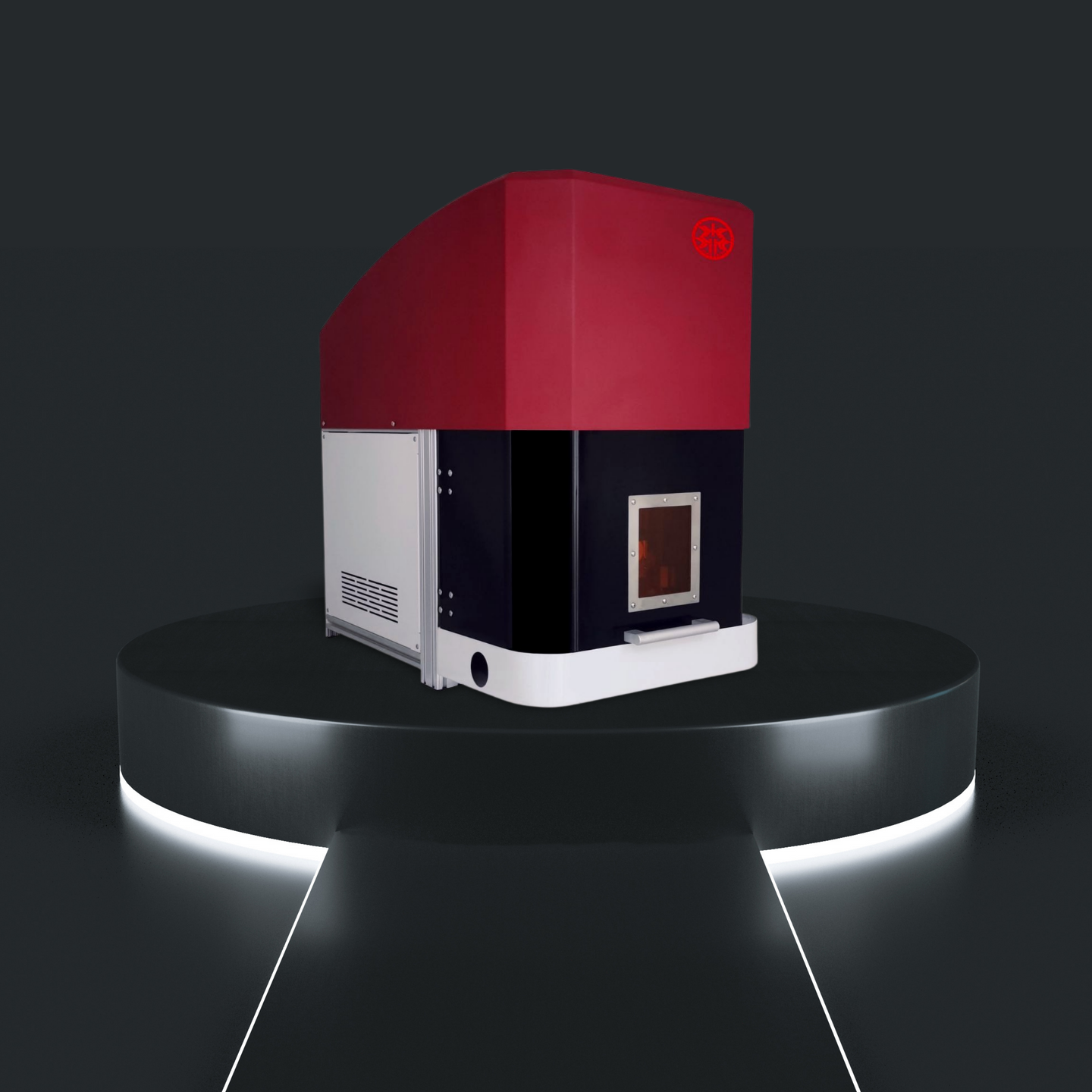

5/10/15W UV Laser Marking Machine

(Water Cooled)

3W UV Laser Marking Machine

(Air Cooled)

3W UV Laser Marking Machine

(Air Cooled)

Please contact us for more information!

CONTACT US

GET IN TOUCH WITH US

Just leave your email or phone number on the contact form so we can provide you with more services!